Automation is our passport to the future, and in many respects the future is now.

—Anthony M. Frank, Postmaster General

Automation Increases

The Postal System continued to increase automation—more and more mail passed through fewer and fewer hands along the path from the post office to people’s homes.

But no matter how much automation occurs, people remain part of the process. As machines do more, people still must operate, supervise, maintain, and design the machines. And as the machines become more complex, they present ever more difficult problems for engineers to try to overcome.

“You have been pre-approved...”

From Salt Lake City to Ann Arbor, Michigan

Judy Franklin is now a junior at the University of Michigan. Like so many other college students, she receives a pre-approved credit card application. How it reaches her is a lesson in postal automation.

Judy’s name and address were part of a database sold to various credit card companies. A program automatically printed out letters and envelopes to people on the database, complete with a barcode that could be read by postal equipment. The credit card company shipped pallets upon pallets of these letters to the Bulk Mail Center, where the company is given a postage discount for the shipping and for using the barcodes.

Once Judy’s application reaches her regional Processing and Distribution Center, it is fed into a Carrier Sequence Barcode Sorter. Using the preprinted barcode, this machine sorts the mail into the final order that the mail carrier uses to deliver it on his route.

Engineers’ Stories

Lynn Robbins

Engineering is a field where young people can make a difference.

—Lynn Robbins, Head of the Process and Quality Management Group, Siemens

For more than 20 years, Lynn Robbins has worked on the development of many innovative pieces of postal automation equipment at Siemens—from optical character readers to delivery bar code sorters. She has progressed through engineering and project management in various leadership roles to her current position—Director of Process & Quality Management.

In engineering, Robbins sees one thing as most important—you have to be a problem-solver. According to Lynn, a primary capability of an engineer is a desire to solve problems. "Young people who enjoy the challenge of puzzles— along with the determination to solve them, no matter how difficult—should consider engineering as a profession."

Another important characteristic for aspiring engineers is the ability to work on a team. Working with any piece of advanced technology will require a whole team of engineers with different skills. "We break things apart here. We give certain tasks to certain engineers, because one engineer doesn't do it all. And then we integrate what they do back together."

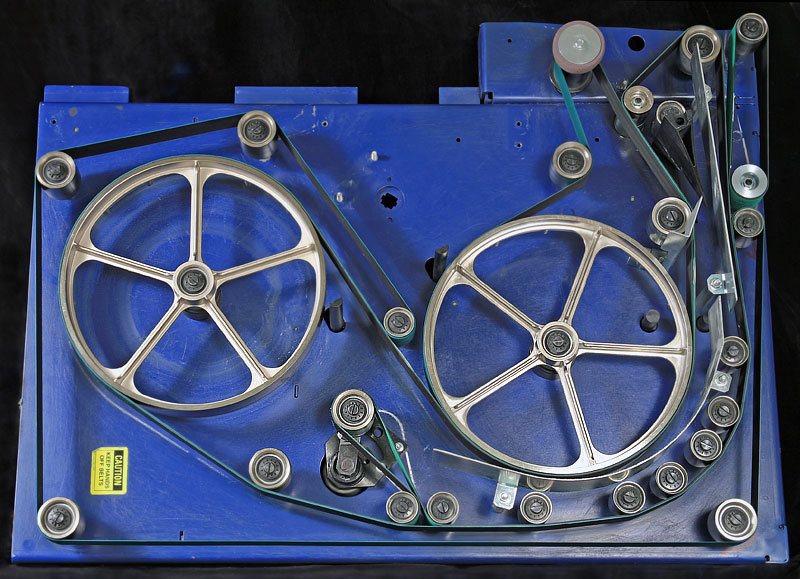

"A machine like the CSBCS will have people working on all sorts of different pieces—diverter gates, camera, the barcode technology, the paths—no one person works on everything… What you see is a collaborative effort, integrated into one system."

Barbara Trower

You're seeking real solutions to real problems in real time.

—Barbara Trower, former Manager of Flat Mail Technology, USP

Barbara Trower grew up in Carter County, Kentucky, and went to college at Eastern Kentucky University as a biology major. She hadn't always planned on going into engineering, but said "I always wanted to be in science or a technical field."

She ultimately moved to the Washington, D.C., area and entered a specialist training program at the US Postal Service. After studying various areas of engineering, she became a materials engineer at the USPS lab. She loved the position: "I was happy as can be in my lab, with my scanning electron microscope and all of these instruments."

Not long after, the Postal Service began investigating new equipment for automation and optical character recognition. Trower’s boss encouraged her to go to Chicago and do some of the testing. There she became a program manager, leading a team of engineers to think of solutions to modern postal problems and creating specifications for new equipment to be developed by contractors.

Trower sees the scientific method as a crucial part of the work of an engineer: "You collect data, you observe, and you analyze results. You make determinations based on the information collected and the results that you find."

Mike Heaton

A systems engineer is the very first person on a project ... the people that take a problem and turn it into something that's real.

—Mike Heaton, Systems Engineer, Lockheed Martin

Mike Heaton's father was an electrician for a railroad company. From childhood, he remembers being fascinated with how electricity made things work. "I always was building different things from used parts, like making alarm systems out of doorbells, or taking old telephone handsets, and you could hook them up to a battery, and you could talk between rooms without shouting."

Heaton attended Iowa State University as an undergraduate and began training as an electrical engineer. He shifted interests in college, and he pursued a degree in industrial technology because it allowed him to study many different aspects of engineering. This led to his career as a systems engineer.

"Most of the technologies that get produced have many different engineers involved . . . mechanical engineers, electrical engineers, software engineers, human factor engineers, and several other types. The system engineer identifies what engineering skills are needed to make a real object."

When asked what advice he would give to people interested in becoming engineers, he had this to offer: "I would get experience as a specialist, and then become a generalist to move forward." He added, "Learn a foreign language.” Engineering is a diverse profession, and you need to be able to communicate with people from all around the world.